The Henry Royce Institute for Advanced Materials has appointed an expert team comprising ScotCHEM, Perspective Economics and Urban Foresight to engage stakeholders across the materials science community in the development of a new National Materials Innovation Strategy.

ScotCHEM is the project lead and, with the team, will expand on the Framework for the strategy, working across the research community to develop both the econometric data and the wider underpinning evidence necessary for scoping, definition and appropriate groupings of:

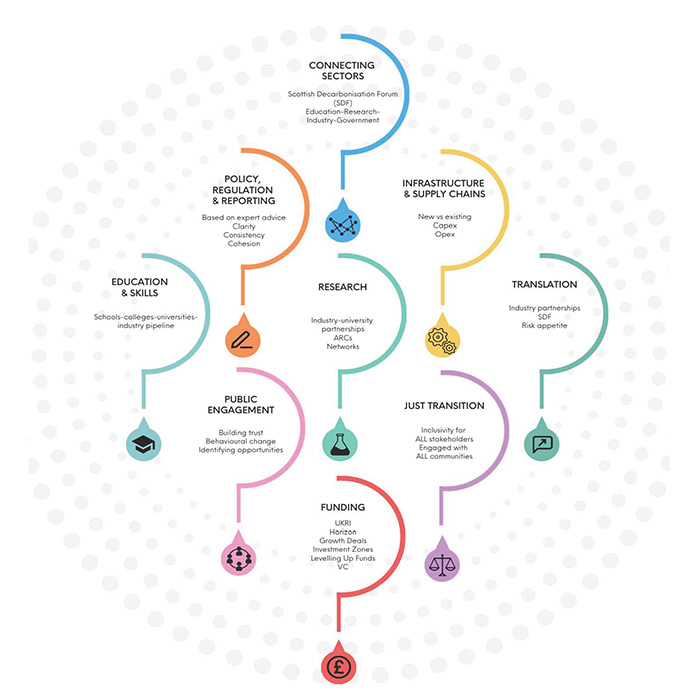

- National and industrial sector priorities, including trends and drivers, market needs and industrial sectors

- Key application and process developments to which materials innovation can contribute via value-creation opportunities

- Material innovations to support these applications and processes and further highlight the need for cross-sector collaborations

- The associated non-technological supporting enablers, such as skills development, regulation and finance

The project team will work under the direction of the new Materials Innovation Leadership Group, which has been established by Royce to oversee and champion the development of this important new Strategy that will tackle the major challenges and opportunities that lie ahead for the UK.

Development of the Strategy will run from now until the end of 2024, with the first stakeholder workshops being planned for later this year.

Materials underpin manufacturing, and the UK is one of the largest global manufacturing nations, contributing £203 billion every year to GVA and supporting 5 million jobs. 84% of this manufacturing takes place outside of London and the South East.

We look forward to working with industry, government, academia and the 3rd sector to develop this significant strategy for the UK.

For enquiries, please contact NSMI@st-andrews.ac.uk

Keep up to date with the Strategy development – sign up to the Henry Royce Institute Newsletter